The Black Pearls of Gambier are world know, and often wrongly referred to as Tahitian black pearls. There are no pearls cultivated in Tahiti, there are only pearl farms in the Gambier Islands and in a few of the Tuamotus atolls. The Gambier Islands’ waters are exceptionally pure, rich in plankton, and have the ideal conditions for pearl farming.

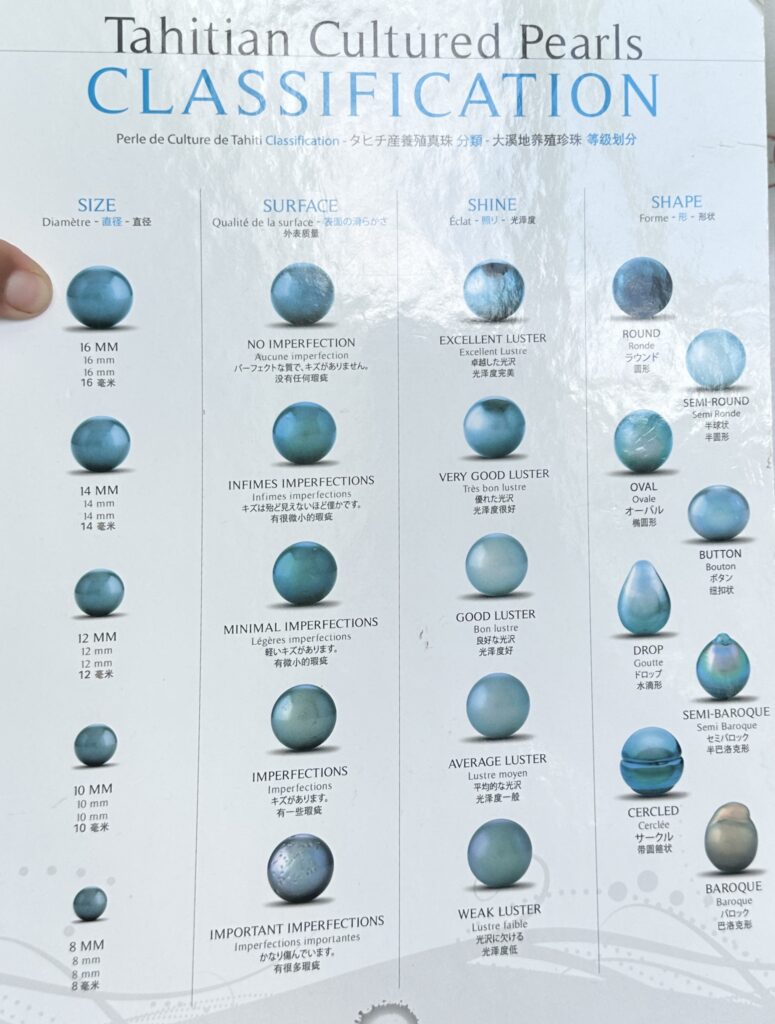

These pearls are considered among the most beautiful and valuable in the world due to their unique luster, deep rich colors and high quality. Their rarity and stunning natural shades make them highly sought after. Unlike other pearls, black pearls are naturally dark, not dyed. The pearls can have a wide range of colors beyond black, including peacock green, aubergine, blue, silver and gold.

Together with some cruiser friends, we set out one day to visit a local pearl farm, Nanihi Pearl Products, which is located on the western side of the main island of Gambier, Mangareva. We were picked up by car on the main dock, and transported over the island, where one of the pearl farm owners, Mohea, and one of her staff, Kevin, picked us up by boat.

We learned about the operational aspects of pearl production, and Mohea took us through all the steps.

1) Producing shells: A dark plastic ribbon that resembles areas where the shell would attach themselves in the wild, are used for growing the shells. The babies are released from the mother and attach themselves to the ribbon. In the old days, they used trees, but nowadays unfortunately using plastic is more efficient, and is preferred by all pearl farmers.

Mohea did recognize that this pollutes the ocean, and that she wishes she could use something else. They do reuse the plastic ribbons, but this also means they leave a lot of plastic waste in the ocean when they clean them.

All of the baby shells are grown on the other side of the island, on the eastern side of the bay by the capital, Rikitea.

2) Growing the oysters: This means removing the young oysters from the plastic ribbons, and placing them into protective casings in the water. This is a two step process, based on the size of the shells. These casings are cleaned every three months, to ensure the shells stay healthy.

3) Inserting pearls: A pearl nucleus is the start of this process. The nucleus is a round bead from another shell that is inserted into the oyster together with mantle tissue to create a pearl. The pearl nucleus is most often from the Mississippi River in the US.

The process of inserting the nucleus into the shell demands a precise operation. A grafter is a a skilled technician who surgically implants the nucleus into the oyster to create a cultured pearl. Most grafters are Chinese, and their grafter was currently on holiday in China when we were there.

The initial process demands that you place the nucleus together with some skin from another shell into the stomach of the oyster. With every 20 oyster, one is sacrificed to be used as providing skin for pearl production. We did, however, watch the process of removing a pearl and inserting a new one, which is a much simpler process.

Most of the meat inside the oyster is reused as a fertilizer in the garden of the owners of this pearl farm. The only eatable part is the muscle, which we got to taste raw. It is delicious and has a delicate taste. We liked it so much that we purchased a few kilos as our freezers are emptying out of sea food since we cannot catch fish here in Gambier (due to the ciguatera algae toxin living in reef fish here).

As part of the experience, we were allowed to pick a shell, learn how to open it, and “win” the pearl inside.

Besides learning about the pearl production, we also learned about the commercial aspects of selling the pearls. The owners of this particular pearl farm have been very entrepreneurial in their approach. They decided to cut the middle man, the wholesaler in Tahiti, who would normally sell the pearls on the world market for them.

Three years ago, Mohea travelled by herself to Hong Kong, for the world’s largest pearl trade show. She was only there to observe the first year. She returned the following year and had her own booth. She will repeat the same this year, and plans to go there in September when the trade show is happening.

There are a few stores in Gambier where we can buy local pearls. They are selling locally produced jewelry, as well as pearls that we could use to make our own jewelry. As we have been inspired to make bracelets by our friend Karmen from our buddy boat, SV Sauvage, we decided to buy pearls for our own production.

We also visited another store in Rikitea, that was very different from what we normally would think of with a jewelry store. It was set up at a private house inside the kitchen, and had a lot of diversity to offer. We bought the pearls and got them drilled for us to produce our own jewelry here.

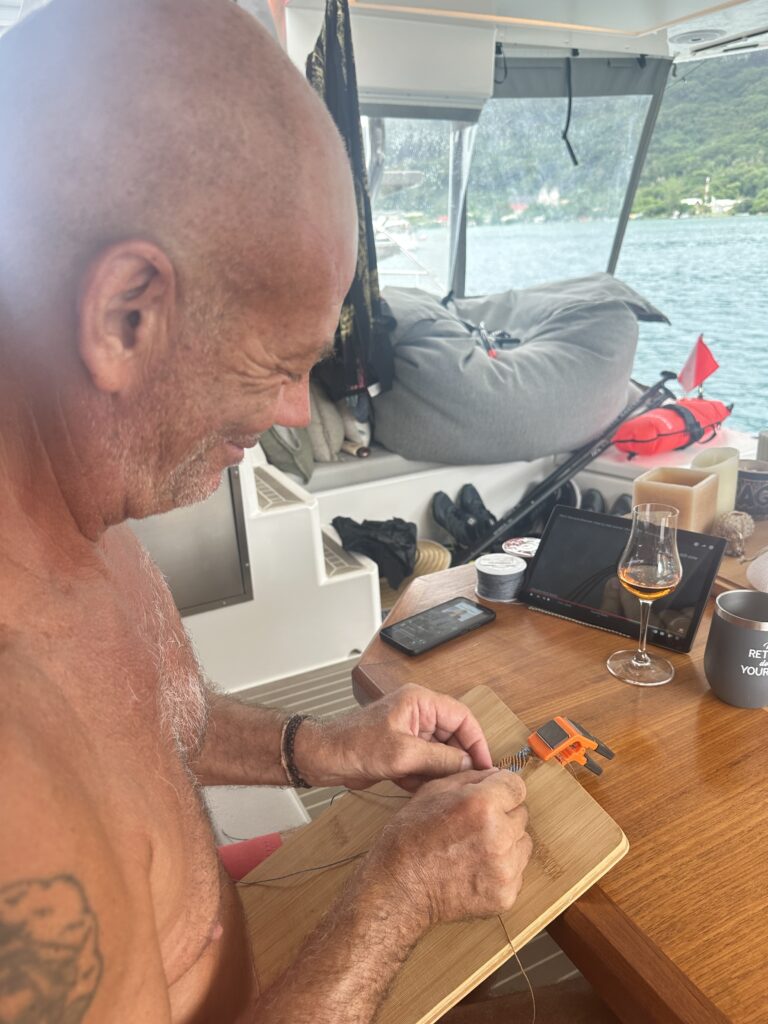

Then, the final process of exploring the unique Gambier pearls, came about on our boat, where we have made plenty of bracelets. We had a fun couple of days when the kids visited as well, where we each made our own bracelets.

We purchased a few extra pearls from Nanihi Pearl Product and will continue to make some more own designed jewelry. It’s a fun and social boat activity which we both enjoy!